1 min read

Thinking differently in 2020

I’m going back 20 years for this one. In 1999, sitting on the cusp of the millennium, we were all focused on the rollover of the year from the –99 to...

I heard someone in an interview the other day say consumers wanted things to return to pre-COVID levels. The speaker believed that people didn’t care where or how things were made – spending was returning to “normal.” I disagree. Everything I’m reading about the post-pandemic consumer says that thing have definitely changed.

Several mega-trends have emerged that I don’t feel will leave soon: personalization and the increased desire to buy-it-on-my-terms. People want to purchase items that are or appear to be built for them and they want those items delivered to their doorstep or their car; “come to me so I don’t have to come to you.” For those who have taken advantage of box-of-the-month subscription services from Christian book clubs to those that sell vices, you experience those each time you purchase. While the box is identical for all participants, it seems to be written just for you. The marketing and materials they provide speak directly to you. It’s targeted and reaches the mark. They are delivered to your doorstep and seem to be made for you.

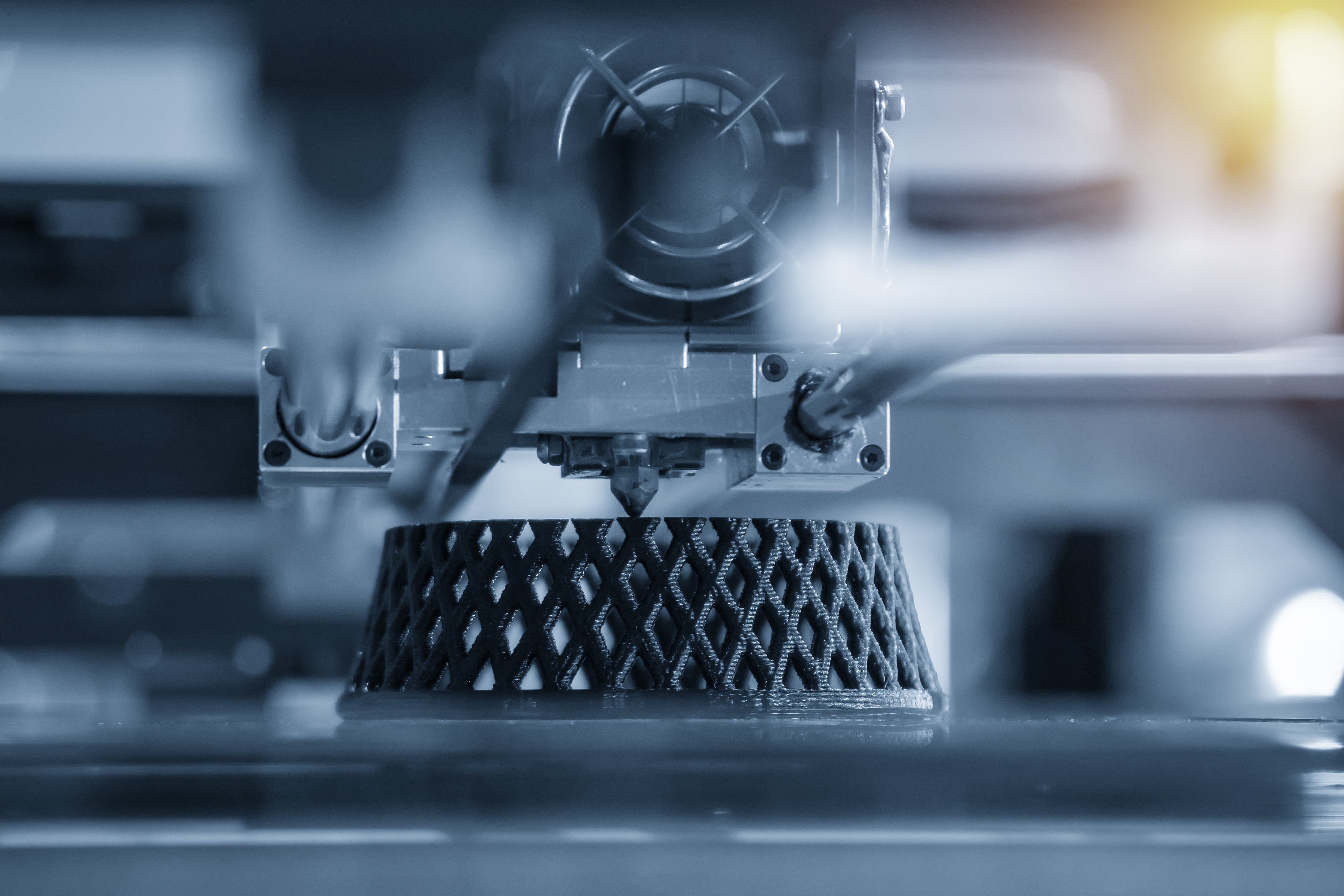

I believe the manufacturing sector must consider how these trends and the impact of permanent or semi-permanent work from home affect the industry. We’ll spend a few weeks talking about these trends and what you can do about them to compete. From custom shop orders to personalized delivery, there are ways to engage both your consumer and your employees to make your business and your shop stronger.

When we first started the business, “job shop” was a small, somewhat simple shop. They did one thing really well and were those that handled smaller orders or cheaper parts. The difference between shop operators in a job shop and those in a tier 1 or tier 2 supplier to corporate entities were substantial. Even in the software industry, we saw this. Software tools that were “job shop” offerings did work that was less complex than those of us who served the Fortune 50.

Today, that’s shifted as well. A job shop today is a specialist. The processes they do for their customers are not simple and often not easy to copy. In manufacturing, a job shop may be a place that you outsource specialty processes (think chroming or painting as an example). These processes require complete accuracy and special considerations in the environment with dust-free areas and highly lit areas that may be more difficult for part manufacturers to implement side-by-side with grinding, cutting, stamping and other key manufacturing processes.

Key to competing in today’s marketplace, you have to avoid commoditization. That is a race to the bottom of the pricing ladder. Job shops can use this opportunity to lean into the new trends and push to the front of the pack. Areas to consider might be packaging, shipping and even customization of the work itself.

Contract manufacturing is another manufacturing sector that can use both customization and delivery to its advantage. Where a job shop focuses on one-and-done, a contract manufacturer may be hired to produce a set of parts over time. These longer-term contracts are difficult to win but get sticky over time like software. Once you become a resource for a company producing their parts, and if you do a great job performing for them, it’s somewhat easier to win the next contract. Original engineering and design are done and, as long as you can meet both the time and cost demands of your customers, you have everything you need to move forward.

There are smart tools (and SMART tools) that these businesses can use to keep track of all the work, make more money on each job and be more competitive. But first, let’s discuss a third area of manufacturing: engineered solutions. These manufacturers often keep a robust team of engineers on-hand to help their customers design their products or turn their customers’ designs into manufactured engineered solutions, complete with the instructions of how to produce them. These services are a top-tier expense for companies that use them. Similar to the job shops that are specialists, engineered solution manufacturers provide an entire set of outsourced departments to companies that use them.

An additional challenge that these manufacturers have comes when their customer contract calls for the engineering team to provide the engineering design and even the manufacturing steps to the customer as part of the initial delivery. This allows the customer to “shop the work out” after the initial delivery. How can you be more competitive in that market?

In all 3 cases, managed customization and delivery are ways to increase your value and “stickiness” with your customers. We will talk through these over the coming weeks in a series of pieces on how job shops, contract manufacturers and engineered solutions companies of all sizes can be more competitive, grab more market share and make more money doing it.

We believe in the critical importance of manufacturing for companies of all sizes right here in North America. We are a software company that believes in standard toolsets affordable for shops from 20 to 200. We believe in finding manufacturers the tools they need to work, whether it's a simple Google doc, an Excel sheet or a Production Control system. To learn more about meeting your targets for 2021 or just getting a question answered, visit us at CIMx Software.

1 min read

I’m going back 20 years for this one. In 1999, sitting on the cusp of the millennium, we were all focused on the rollover of the year from the –99 to...

Post COVID, targets are different and work has changed for almost everyone. This is nothing new and it seems that everyone is writing about it. But...

Trust. It’s a firm belief in someone or something. The definition even goes so far as to say it’s acceptance without evidence or investigation. We...