Are Your Paper-based Travelers Holding Back Your Shop Floor?

Inefficient, annoying, error-prone and wasteful, many times paper-based work travelers are the source of countless shop floor problems and might be...

3 min read

David Oeters : February 26, 2014 at 6:15 AM

Humans love to categorize. It helps us make sense of things. We bring order out of chaos by putting things in their place, grouping the countless multitude into finite categories.

The problem is, sometimes we can be fooled into bad decisions by simplistic or faulty categorizations. For example, take a look at shop floor solutions. Software systems that monitor and support manufacturing operations, including paperless manufacturing, MES and MOM systems, can be grouped into two categories: template-based and behavior-based. One category offers a clear advantage to shop floor process improvement.

Template-based Systems

Template-based SystemsA template-based solution requires people to conform their work to screens of information and specific sequences of data input. Users work from the forms and templates that guide the work on the shop floor. Think about the ERP screens that are highly formatted data collection vehicles which digest transaction information. They can be easy-to-use, with a structured format that drives consistency, but the system struggles to adapt to changing processes or user needs.

There are many template-based systems on the market, and people routinely input data into them and digest output information with little regard for whether it improves efficiency or profitability. These do the job, but there is little opportunity for improvement. People just feed the information into the prepared slots, and gather instructions from other slots… which feels very Orwellian, but I digress.

A behavior-based system adapts to shop floor processes and behavior, including manufacturing work flow. The architecture is structured around screens or windows users edit and reconfigure as needed. Key data can be collected at any point in the process. Users configure the screens, and attach or open the information they need. The entire system can be quickly adjusted. This way, the system adapts to support behaviors that produce an efficient and productive shop floor. The system becomes a foundation and tool for process improvement because of the adaptability.

In a behavior-based system, one production line or area might require text-based work instructions and multiple measurements. Another area in the same plant might use assembly work instructions with images or videos, and require only a few key quality data collections. Behavior-based systems are flexible, designed to optimize work flow process through tools that promote and support behavior under control of local management. A flexible behavior-based system can use existing work instructions enhanced by software tools with minimal set-up and preparation.

Supporting Shop Floor Process Improvement

Supporting Shop Floor Process ImprovementProcess improvement programs, such as Lean manufacturing or Six Sigma, optimally support a behavior-based shop floor solution. The only way to optimize work flow is to configure the support system to best match the value-added activities at each point in the process. Forms and fixed templates dictate a structure that limits adaptation. In a template-based system, the shop floor processes will struggle to adjustments to improve the processes, adding a significant amount of non-value-added work.

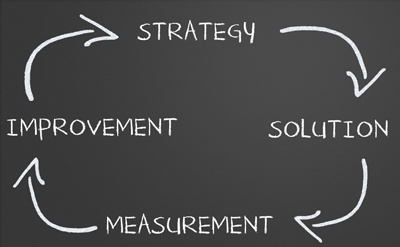

Process improvement requires behavior-adjustment, which template-based systems don’t promote. For example, the Six Sigma process requires analysis of the work flow. When a source of quality escapes is identified, processes will be changed to reduce variation. A behavior-based system can be configured to the new process, and ensure the shop floor incorporates the new process into the work flow.

In this example, as a company improves steps in the work flow to reduce variation, data collection will change. Using the same templates and forms after adjustments have been made will do nothing to promote a change in behavior. Additionally, in a template-based system, moving material over to new templates will often require significant work, in addition to potentially expensive service charges for adjustments to the system itself.

Success with Six Sigma, Lean Manufacturing and process improvement requires adaptation and adjustments to shop floor behavior. You will need to change the flow of information, adjust data collection and record keeping in the support systems. This can be done in phases across manufacturing operations. This process isn’t how a template-based system is designed. A behavior-based shop floor system is adjustable, supports process improvement, and offers a foundation for promoting behavior adjustment.

Look closely at the characteristics of the software system you evaluate. Can you use your current work instructions with the system? How much control do you have over the system? Does it work with your process, or will you have to adjust your process? The difference between a template-based system and a behavior-based system is the difference between successful continuous improvement and watching error-prone processes and inefficient behavior slowly take root again on your shop floor after a process improvement campaign.

Inefficient, annoying, error-prone and wasteful, many times paper-based work travelers are the source of countless shop floor problems and might be...

3 min read

We often overlook the small benefits of paperless manufacturing and manufacturing software solutions, benefits that may have the greatest impact for...

1 min read

Smart businesses have discovered data is a valuable asset, but struggle to deliver shop floor visibility, letting manufacturing data slip away. By...