1 min read

What the Size of Your Shop Says about Your Production Needs

Which ERPs Can Manage Production? | Part 1 of 2 I’m going to save you some time and get straight to the point; there are really only 4 ERPs that are...

3 min read

Ed Deaton

:

February 19, 2019 at 9:00 AM

Ed Deaton

:

February 19, 2019 at 9:00 AM

In part 2 of our ERP for production series, we cover the critical factors to understand when researching production systems. To learn more about requirements based on your size revisit Part 1 where we discuss the difference between “Growing” and “Influencer” sized manufacturing needs.

Regardless of size, every manufacturer needs to keep these 5 factors in mind when selecting their next production control system:

Demand clear upfront pricing

Just like in every other purchase in life, expect to get what you pay for. Cloud systems are going to be less expensive (generally) but struggle to integrate with other non-cloud platforms, install as an empty shell (without your existing data) and scare away potential customers who require higher levels of security (aerospace, defense, medical, etc).

The ideal system has an installation cost of $20,000-$50,000 with license structured pricing for the years to follow. This guarantees you’re only paying for what you need, your shop has room to grow and the software company you’re working with is invested in your success. The more you grow, the more licenses you’ll invest in which keeps relationships strong for generations to come.

Request a live demo

Canned presentations ignore the actual series of steps that are taken to execute an action and only show you their system in a perfect scenario. It’s good practice to try to throw the presenters off their game as they demo to your team. Demo systems can be incredibly misleading if you allow a company to stick to their script, so protect yourself. Ask tough questions specific to your processes and really consider how they respond. Ask how other manufacturers that use their system have overcome similar problems in the past and relate it to your own situation.

Don’t expect a demo team to know everything, but if you find they are constantly putting you off, it should be a red flag for your relationship down the road.

Never fall in love with gimmicks

Have a strong list of ranked priorities leading into your demo, even share it with the vendor ahead of time and make sure they meet your needs. Too often manufacturers get distracted by how a system can digitize their existing problems rather than eliminating them. Ignore the fun widgets and be direct when you question their team.

This is also a good place to mention standard versus add-on functionality. Tell their team upfront that you want to see what is in standard product first. This eliminates the surprise up-scoping later on in the process.

Know your shop’s needs

Most shops don’t have the luxury of waiting multiple years to see return on their investment. You need immediate impact and room to grow. Know before you buy how long it should take to hit your goals and how each vendor accommodates for the success they’re promising you.

You don’t have the time to restart this process over again in 3 years so commit to a long-term strategy before you write that check.

There is no such thing as simple production

All manufacturing is complicated. It only gets more complex when you add multiple plants that employ entire communities. If what you did was simple, everyone would be doing it.

The truth is that every job that gets released to your shop floor requires intense planning, professional execution, pages of records and the level of quality your customers have come to expect.

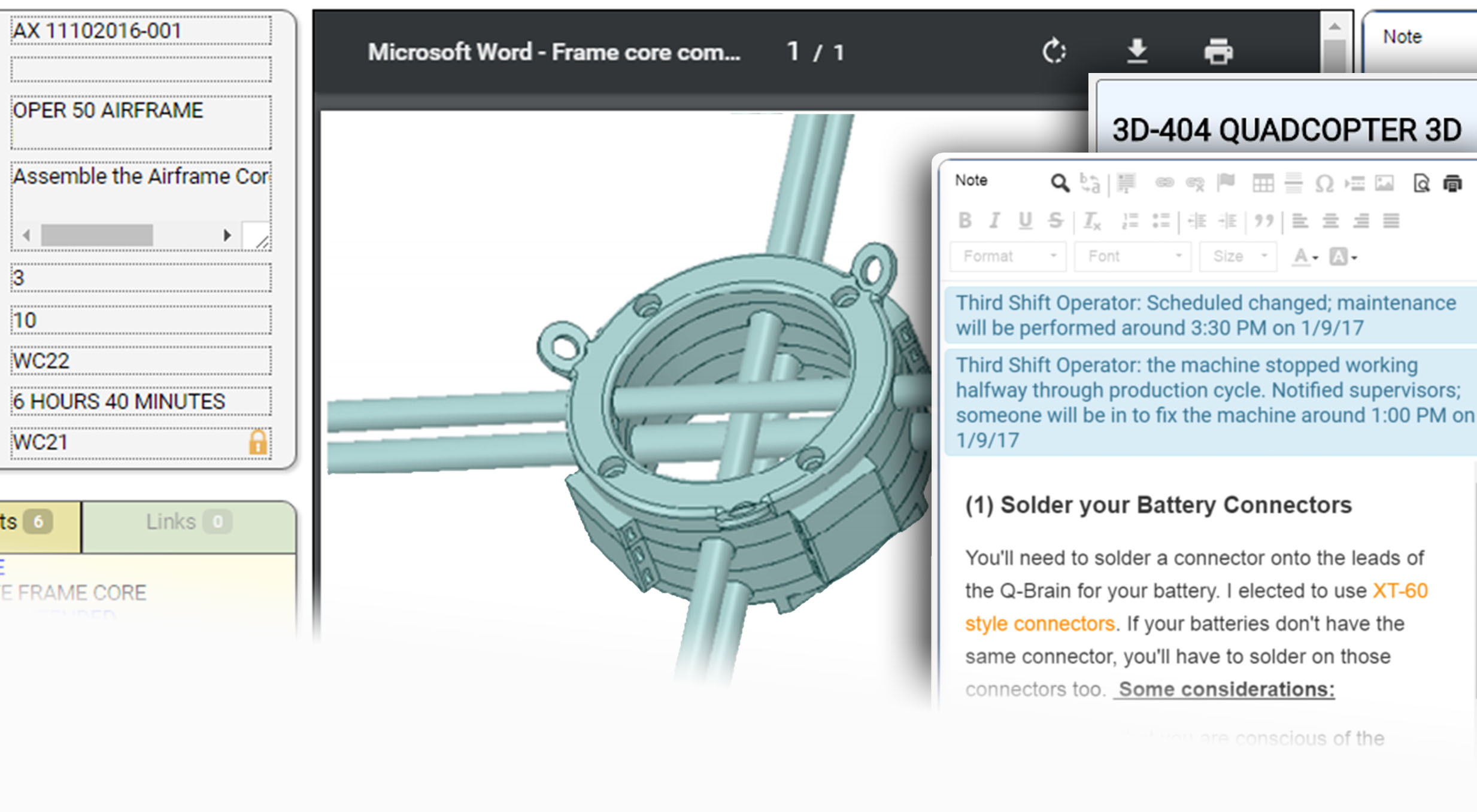

The unique requirements demanded by your customers change on every job. Machinery goes down, Operators call in sick and the external resources you rely on (materials vendors, outsourcing agents) ship late: all of which negatively impact your schedule. ERPs simply do not have the production intelligence to understand which resources need to be used, replaced or reordered until it’s too late.

Ask software vendors to demo how their system reacts when workflow doesn’t go as planned. That gives you the opportunity to see how a system reacts to real-world workflow and proves your demo team actually understands what they’re talking about.

Catch up on the series with Part 1:

“What the Size of Your Shop Says About Your Production Needs”

Your Next Steps

Take your time and consult with both the other leaders in your network and the experts who know how to support your needs. The more you know about your plans for the future the more smoothly the rest of the process will flow.

Connect with a CIMx Expert to find out how other manufacturers have taken control of their production processes. When you're ready to get to work on permanent error elimination, schedule your live demo of Quantum® with a CIMx Expert.

1 min read

Which ERPs Can Manage Production? | Part 1 of 2 I’m going to save you some time and get straight to the point; there are really only 4 ERPs that are...

A company relying on paper-based data collection isn’t giving their shop floor the tools they need to compete in the modern manufacturing market. ...

No one enjoys researching shop floor systems. You have plenty of other responsibilities on your plate and frankly, you didn’t get into manufacturing...