Legacy Systems are Agony

We’re talking about legacy through to March. It’s still the first quarter of the year and now’s the time to make a change to support your team. If...

I take in every executive education experience I can. I’m a bit of a junkie. I love being overwhelmed by ideas (firehose-style). That’s when my brain really starts cooking. At an event I recently went to, they were talking about how to be where our customers are. That’s an obvious thing in marketing; it’s meant to get you the recognition that you need for your potential customers to find you.

But let’s take that deeper.

In the world of manufacturing – quite unlike marketing in the B2B space – things are often moving quicker than you can track them. Customers – your customers – want you to be able to bid on a piece of work for them (an order or a possible job) and then get to work as soon as possible after they say go. Being where your customers are in manufacturing involves you knowing exactly what work you can accommodate, how much it will cost, and when you can get it complete.

That’s not easy in manufacturing. You’ve got people, skills, inventory, timeline, and safety to worry about. You can’t just pick up all the work from one area to accommodate new work. And yet manufacturers are doing that every day. It’s often a “do whatever it takes” mentality out there and you both need and want to win the work.

What if there were a different way?

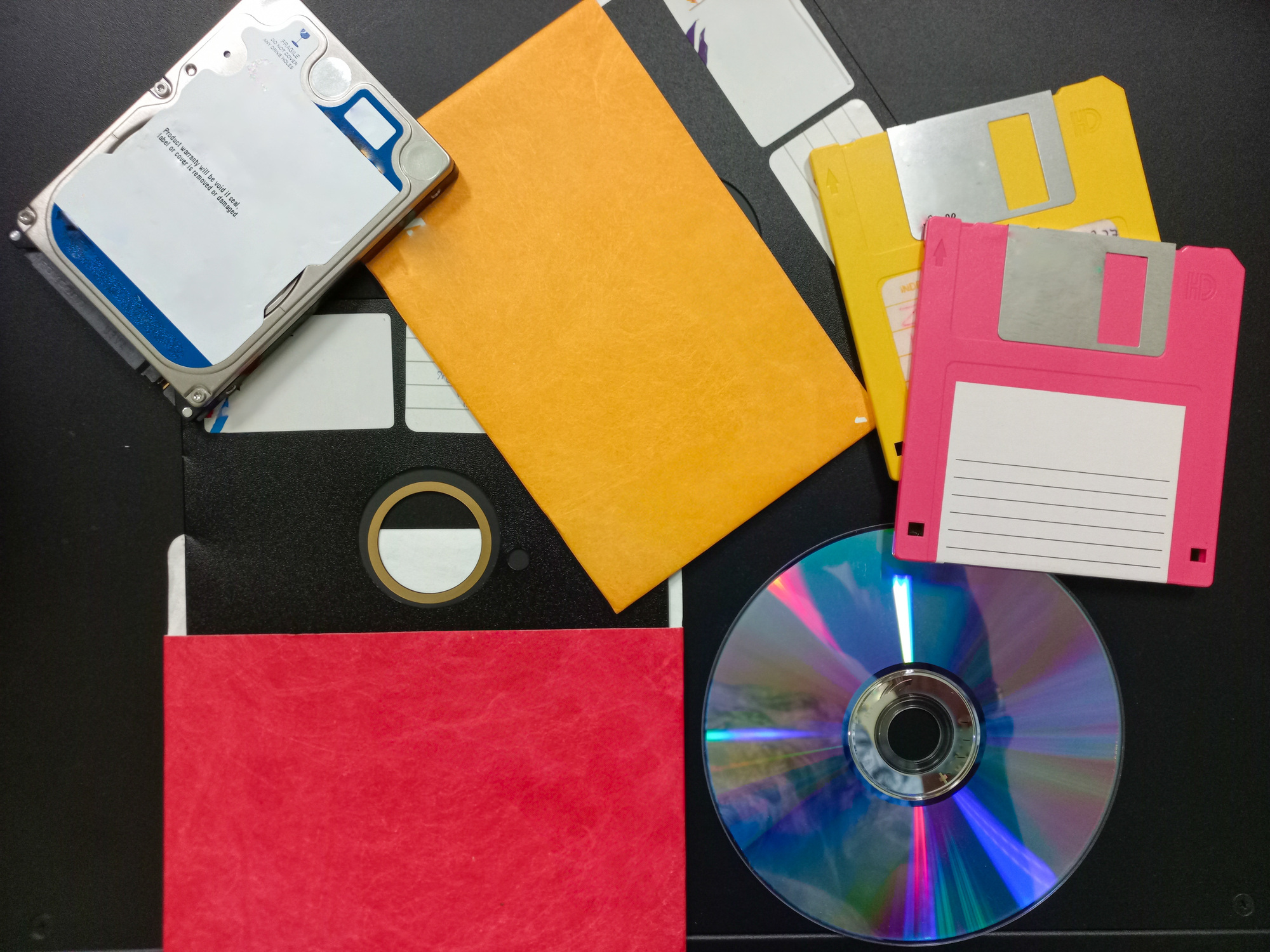

If you knew -really knew – how to fulfill any demand a customer put in front of you, how would that change the number and likelihood of winning work? There are some very specific steps you can take to get there. This works best in a digital environment; it provides you with the flexibilities that you need to make a decision now, and pivot when you need to, even if that is a repeating pattern. Working in a paper-based model or with spreadsheets makes it almost impossible to pivot as you will need to in order to accommodate your customers’ demands.

Imagine your team taking a call from one of your customers. It happens every day (or we surely hope it does for you). They’re calling to see if they can reorder something they’ve had to make for them before. Or, they’re calling with something new – even more challenging. They want to know three things:

Your team has three questions, too. They’re almost identical. They want to know if you can do the job, when and how much it will cost you so you know how much to charge. These are critical to your team knowing if you should take the work. Not all jobs are ones that you want.

In the world of manufacturing supported by software built to do just this, these answers are directly at your fingertips. You should be able to answer these questions in a moment, as it determines, likely, whether you will win the work or not. And you definitely want to win it if the answer to your third question is that you’ll make money on it because you’re certain of a margin based on your bid and you’re secure that your bid is based on the real-life experiences of your team. You will need a few things to get there.

These steps make you more responsive. It allows you to work with your customer, right where they’re at, and make sure you both agree to the plan before it’s put in motion.

If you want to meet your customers where they are and, most importantly, win more work, you need to explore the world of digitization of at least some of your processes. The impact of this should be that your team has the information they need at their fingertips and that it is situational. They should be able to move data around – dates, work, jobs, routings, materials – in order to maximize what’s possible and, even better, the system should do that for them so they can down to the work itself.

We explore the world of manufacturing every week and what’s possible for you to remain or get competitive with global demands, changing workforces and ever-changing customer demands. Join us weekly as we explore what’s possible for you and your team.

We’re talking about legacy through to March. It’s still the first quarter of the year and now’s the time to make a change to support your team. If...

1 min read

You may not think a lot about the legacy you leave in the workplace, but it causes me to ask a lot of questions that I think are worthwhile. I try to...

1 min read

Every day, the people you’ve hired to do the work in your shop show up to get it done. They are, quite simply, amazing. I’ve never seen people more...