production control for composite manufacturing

materials compliance

Composite companies need complete records of use for every composite material and a way to control the use of those in production, both in record-keeping and time-out-of-storage to actual compliance to the part specification. This is impossible to do in a paper-based environment. Composite materials are finicky, making composite manufacturing art and science. Non-conforming work is part of regular production and rework is natural. Material usage must be tracked to the genealogical record of the part, to the material itself, the number of times that material has been used and the total time it's been out of refrigeration or open.

Quantum enforces these quality checks, directs accurate workflow and delivers compliance at every stage of production. We have 29 years of experience ensuring that composite companies have the Production Control they require for compliance. Maintain all of your certifications including your MSDS sheets, ISO 9001 and AS 9100 compliance with a platform that's ready to install today and use tomorrow.

Complete Production Control for Production Operations in Composite Manufacturing. Quantum.

every-job visibility

track your team's performance for compliance and effectivity

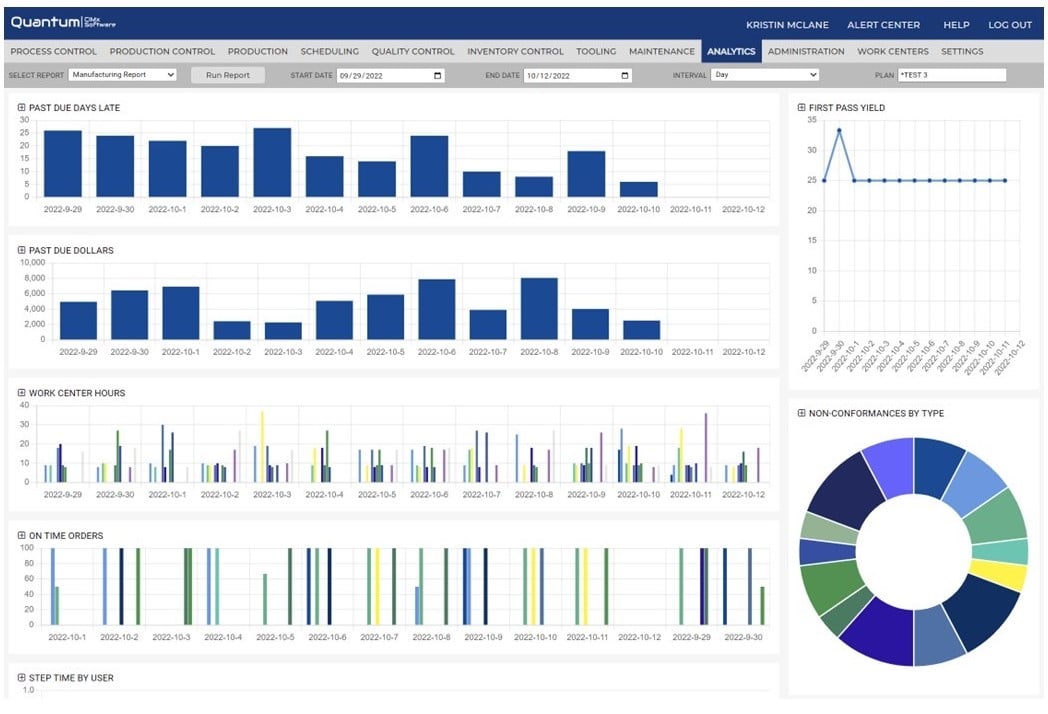

Quantum Analytics gives you complete visibility into your Production Operations team's performance. Track performance of tasks, jobs, orders, people and teams. See trends, forecast resource needs and improve team efficiency with Quantum.

Complete Production Control for your Production Operations team.

process engineering

From control of the material itself through the process of building your parts, Quantum has you covered.

material tracking

Capture the use-by date and the time out of the freezer for each of your carbon sheets. Ensure that the materials you use in each stage of production are compliant.

work certification

Record every composite lot on every part automatically. Control the materials on your shop floor and the people that use them with certification of the lot and the Operators doing the work.

BETTER DECISIONS

non-conformance resolution

Correct each production non-conformance and push automated rework routines to the proper place along with approval of each piece of rework.

work records

Get an automated record of every action by every person that touched the part from the original Engineering through to final inspection and supervisory sign-offs.

not just visibility

visibility and control. only with Quantum.

Manufacturers that build parts from carbon and other composite materials need a complete auditable record of part production, from sourcing to historical record-keeping. Many manufacturers use common programs to keep their engineering and instructions. This does not provide the historical archive that you need for proper compliance.

Quantum ensures compliance to the most rigorous standards of your industry and your customers. Complete Production Control for Production Operations in Composite Manufacturing.

.png?width=500&height=156&name=CIMx-logo-transparent%20(1).png)